16 10/100/1000T + 4 1G/2.5G Copper + 2 1G/2.5G Fiber Q-ODC OM3 (with 8/10/12/16 PoE) , EN50155 OS4 Managed Ethernet Switch; WVI / 24VI / 24TVI input w/ optional dynamic routing, multicast routing, cybersecurity, and hardware NAT

OVERVIEW

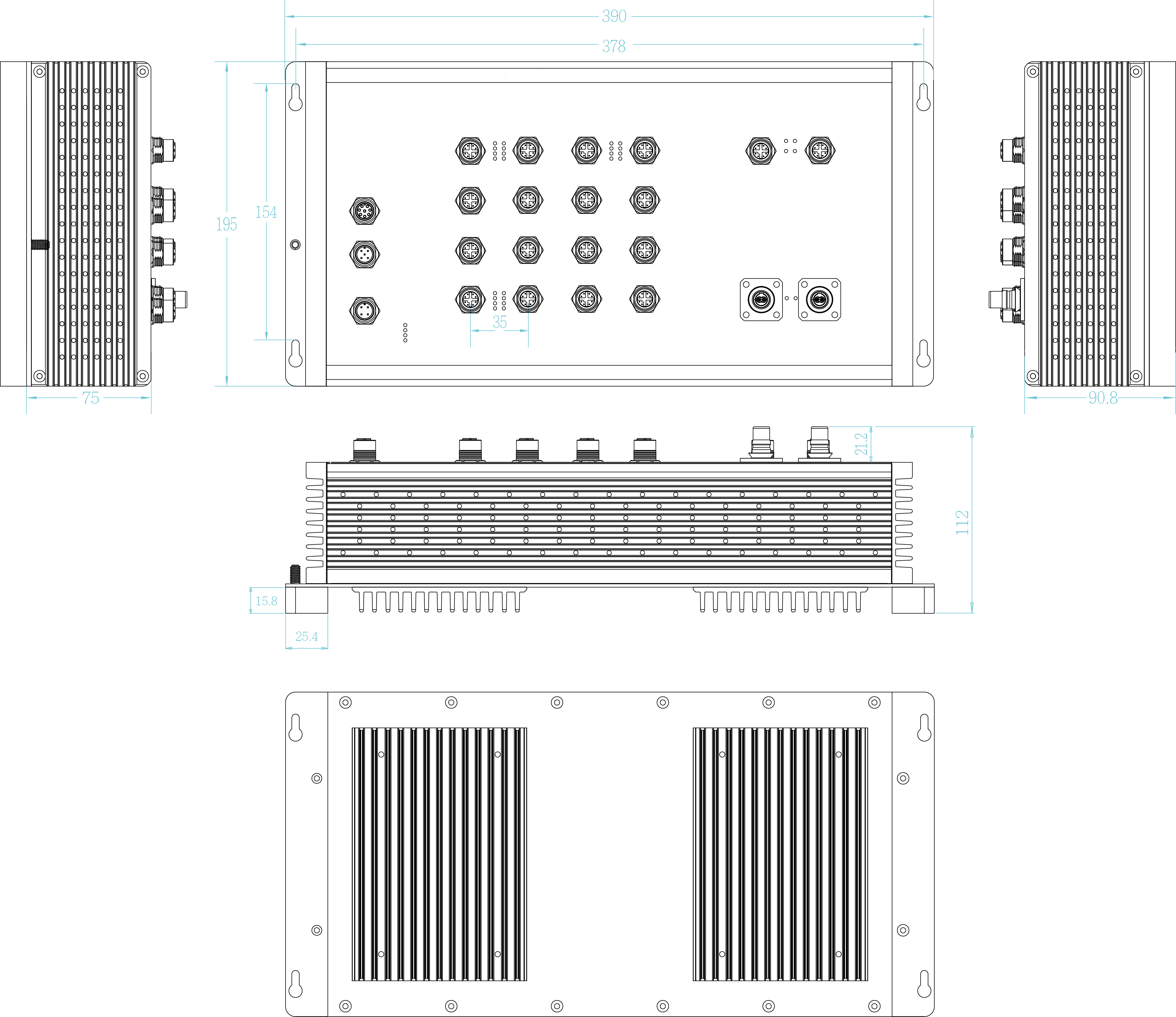

Lantech T(P)GS-R5416MGFT is a high performance L2+/L3 Ethernet switch with 16 10/100/1000T + 2 1G/2.5G Copper + 2 1G/2.5G Q-ODC OM3. PoE model has 8/16 or w/10 (incl.8 10/100/1000T + 2 uplink 1G/2.5G copper) PoE 802.3af/at ports which provides advanced security function for network aggregation deployment.

Lantech OS4 Platform with complete L2 management and upgradable optional L3 & L3Lite communication protocols incl. dynamic routing, multicast routing, hardware NAT, and PTP

The switch runs Lantech OS4 platform which is powerful with complete Layer 2 management features and optional upgradable for future expansion, such as Layer 3 Lite, Layer 3, IEC61375-2-5 (ETBN), R-NAT, hardware NAT, PTP, etc. The PTP V2 supports transparent clock and two step processing that improves network time accuracy and precision. To learn more about the Lantech OS4 Platform, please refer to Lantech OS3/OS4 platform

Enhanced cybersecurity features with IEC 62443-4-1, optional IEC 62443-4-2 compliance & built-in DDoS attack protection

Lantech OS4 platform is designed with high standard of cybersecurity to prevent the threats from network attack such as DDoS attacks. To ensure the safety and reliability of communication networks, Lantech develops our products under strict international security standard and is certified with IEC 62443-4-1 and the switch is also compliant to optional IEC 62443-4-2 standard. To learn more about Lantech cybersecurity software solution, please refer to Lantech OS3/OS4 platform

Up to 8/10/16 PoE at/af ports w/advanced PoE management and PoE galvanic isolation; Ethernet power input galvanic isolation

Compliant with 802.3af/at standard, the PoE model is able to feed each PoE port up to 30 Watt at each PoE port for various IP PD devices. It supports advanced PoE management including PoE detection and scheduling. PoE detection can detect if the connected PD hangs then restart the PD; PoE scheduling is to allow pre-set power feeding schedule upon routine time table. Each PoE ports can be Enabled/disabled, get the voltage, current, Watt, and temperature info displayed on WebUI.

Galvanic isolation between power input and Ethernet power system, also the PoE galvanic isolation provides insulation between the power input to PoE Ethernet ports, preventing cabling and grounding incidents from damaging the Ethernet switch. The efficiency of the galvanically decoupled voltage converters can reach above 90%.

Miss-wiring avoidance, node failure protection, Loop protection

The switch also embedded several features for strong and reliable network protection in an easy and intuitive way. When the pre-set ring configuration failed or looped by miss-wiring, the switch being able to alert with the LED indicator and disable ring automatically. Node failure protection ensures the switches in a ring to survive after power breakout is back. The status can be shown in NMS when each switch is back. Loop protection is also available to prevent the generation of broadcast storm when a dumb switch is inserted in a closed loop connection.

User friendly GUI, Auto topology drawing, Enhanced Environmental Monitoring

The user-friendly UI, innovative auto topology drawing and topology demo makes the switch much easier to get hands-on. The complete CLI enables professional engineer to configure setting by command line. It supports enhanced environmental monitoring for actual input voltage, current, ambient temperature and total power load.

Built-in IEC 61375-3-4 ECN (Ethernet Consist Network) to work with IEC61375-2-5 TBN

Lantech OS4 Ethernet switches comply with IEC 61375-3-4 (ECN) standard. The support of Ethernet Consist Network allows interconnection between end devices located in single consist of train and interoperability with IEC61375-2-5 (TBN).

Editable configuration file; USB port for import/export configuration

The configuration file of the switch can be imported and edited with word processor for the following switches to configure with ease. The USB port can import/export the configuration from/to USB dongle and also to upgrade firmware from USB dongle. TFTP/HTTP firmware upgrade is supported.

Event log & message; 2DI + 2DO; Factory default pin

The switch provides 2DI and 2DO. When disconnection of the specific port was detected; DO will activate the signal LED to alarm. DI can integrate the sensors for events and DO will trigger the outside alarm and switch will send alert information to IP network with traps. The factory reset pin can restore the setting back to factory default.

Optional smart bypass protection on dual 1G/2.5G copper/fiber ports

The bypass relay is set to bypass the switch to the next one when power is off to prevent network disruption. Lantech bypass caters to remain in bypass mode until the switch is completely booting up when power is back to avoid another network lost. Optional smart bypass (one pair copper bypass and one pair fiber bypass) can be activated when switch encounters power failure. (-BT/-BF/-BT-BF model)

Dual WVI / 24VI / 24TVI input with max PoE budget and Inrush current protection

The switch accept 16.8~137.5VDC (WVI model) ; 9~36VDC (24VI model) ; 16.8~56VDC (24TVI model) dual input with Ethernet and PoE galvanic isolation and PoE model can feed 54V output for PoE feeding with 80W budget. The inrush current on initial power up can be limited lower than 10 x nominal current.

EN50155, EN45545-2; EN61373 compliance; Rugged design with high ESD protection

The switch is designed to meet with critical network environment with IP21 aluminum enclosure and M12 connectors for water proof. The switch passed serious tests under extensive Industrial EMI and Safety standards. With EN45545-2 Fire & Smoke and EN50155 verification, it is best switch for railway on-board/track side, vehicle, and mining applications. For more usage flexibilities, the switch supports wide operating temperature from -40°C to 70°C (85°C operation for 10min), which is compliant with the EN50155 Operating Temperature Range Requirement Class OT4.

Lantech is dedicated to providing the best quality and service to our customers. We proudly provide 5 years warranty to our industrial products.

Lantech is dedicated to providing the best quality and service to our customers. We proudly provide 5 years warranty to our industrial products.