Challenges

The most dynamic and challenging part for factory automation floor network is redundancy and real-time. Factory automation needs to be absolutely accurate because any interruption or delay could result in huge amount of lost, especially when the operation is non-stop, 7/24/365. On the other hand, to satisfy the rapid changing industry environment, manufacturing process must have high flexibility than before.

Our Solution

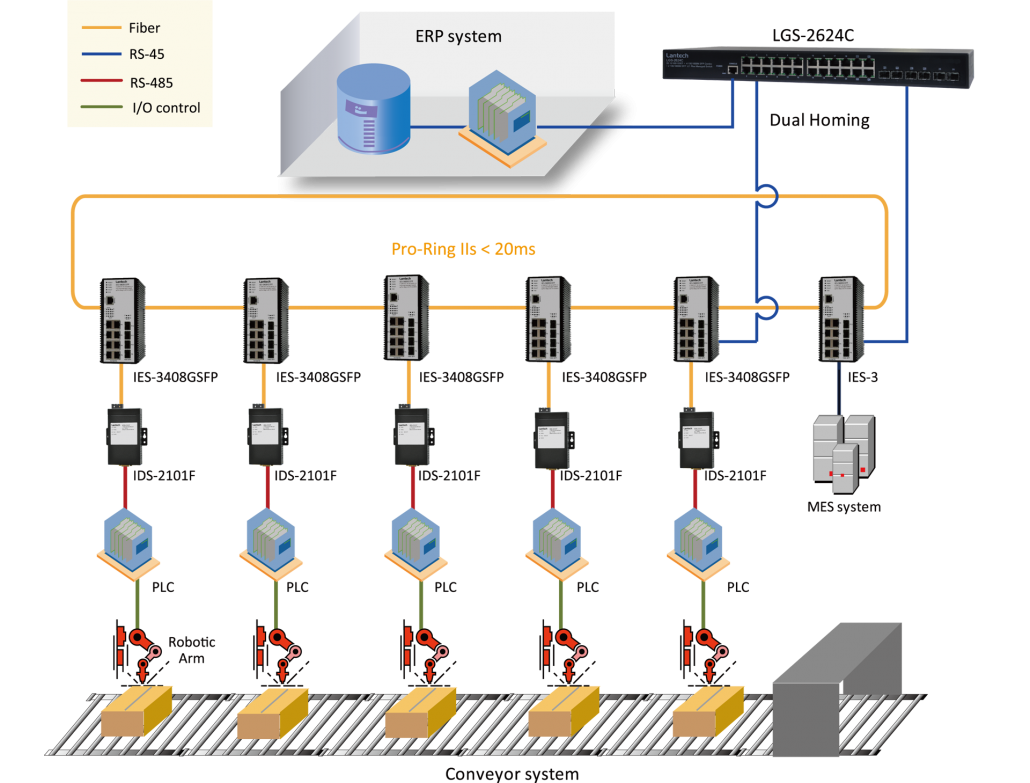

In factory automation applications, the most common structure consists of PLC, DCS, and SCADA. Based on IP protocol, managers are able to control equipments and transmit data to SCADA, where connects with database and then generate statistic data for monitoring the operating status. Lantech’s Pro-Ring system provides the reliable Ethernet network among these devices and software with the fastest recovery time if failure. As the equipments are all utilizing IP protocol and connect to the Ethernet, it’s easier to integrate and change configuration through Internet.

Due to the requirement of absolute accurate data transmission, there is a huge need for real time protocols in factory automation applications, including ProfiNet by Siemens, EthernetIP by Rockwell, and ModBUS by Schneider. The real time protocols were developed by the need of PLC’s connecting with robotic arms, conveyor belts and other automation devices for factory automation. This created the need for switches to be compatible with real time protocols. By collocating with Ethernet switches, managers are able to monitor the status, detect the failure, and solve the problem immediately.

Lantech is dedicated to providing the best quality and service to our customers. We proudly provide 5 years warranty to our industrial products.

Lantech is dedicated to providing the best quality and service to our customers. We proudly provide 5 years warranty to our industrial products.